Introduction

Complex fluid Engineering Laboratory

Professor

Kyu Hyun

Members

Research Interests

Recently there has been a growing interest in “complex fluids”, which include biological macromolecules, polyelectrolytes, surfactants, suspensions, emulsions, commercial polymer melts and so on [Larson 1999]. These fluids are used in many fields of industry as food stuffs, personal care products, electronic and optical materials and plastic products, for many biological applications (see bottom Figure). These “complex fluids” are neither simple liquids nor simple crystalline solids, and thus they do not fall readily within the classical scheme of materials classification because they have unique internal structures with various sizes from micro to nano meter size. Especially, they undergo a variety of deformations (shear, and extensional flow and so on) under the processing. These deformations affect to the microstructure or nanostructure, and vice versa, these structures can also affect the mechanical property. Thus, we need to investigate an interesting coupling between internal structure and flow field. However, in most processing operations the deformations can be large and rapid (nonlinear regime). Therefore, we also need to investigate rheological properties (or mechanical properties) of various complex fluids under nonlinear deformations.

Recent Research

· Nonlinear rheological properties of linear and branched polymer under LAOS flow

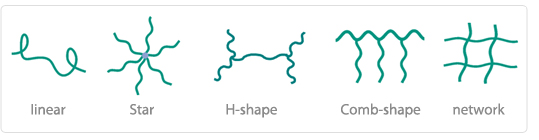

Polymer has various topologies, e.g, linear polymer, star polymer with one branching point, H-polymer with two branching points, comb-polymer with several branching points, or network structure (see bottom Figure). These polymer topologies, especially degree of branching, affect on the rheological properties during processing operations such as film-blowing, melt spinning, blow molding, foaming and thermoforming, furthermore, affect on the processibility of polymer. Therefore, it is needed to distinguish polymer topology and characterize degree of branching. For this, there are many methods to characterize polymer topology. Especially, rheological methods are very popular for distinguishing existence of branching points. It is easy to distinguish whether there exist branching points or not, however it is another story to tell how much it is branched or how much the structure is nonlinear far from the linear structure. Thus we need to develop another method to characterize polymer topology. These days, many researchers try to characterize polymer topology using LAOS (large amplitude oscillatory shear) which is one of nonlinear rheological methods. Hyun et al. (2009; Macromolecules) suggested a new nonlinear coefficient, Q from investigation of the nonlinearity (I3/1) from FT-Rheology. Our goal is to investigate relationship between nonlinear coefficient Q and polymer topology using experiments and simulation results with constitutive equation.

Polymer has various topologies, e.g, linear polymer, star polymer with one branching point, H-polymer with two branching points, comb-polymer with several branching points, or network structure (see bottom Figure). These polymer topologies, especially degree of branching, affect on the rheological properties during processing operations such as film-blowing, melt spinning, blow molding, foaming and thermoforming, furthermore, affect on the processibility of polymer. Therefore, it is needed to distinguish polymer topology and characterize degree of branching. For this, there are many methods to characterize polymer topology. Especially, rheological methods are very popular for distinguishing existence of branching points. It is easy to distinguish whether there exist branching points or not, however it is another story to tell how much it is branched or how much the structure is nonlinear far from the linear structure. Thus we need to develop another method to characterize polymer topology. These days, many researchers try to characterize polymer topology using LAOS (large amplitude oscillatory shear) which is one of nonlinear rheological methods. Hyun et al. (2009; Macromolecules) suggested a new nonlinear coefficient, Q from investigation of the nonlinearity (I3/1) from FT-Rheology. Our goal is to investigate relationship between nonlinear coefficient Q and polymer topology using experiments and simulation results with constitutive equation.

· The time-resolved nano-structure of complex fluid under various deformations using in-situ Rheo-SAXS.

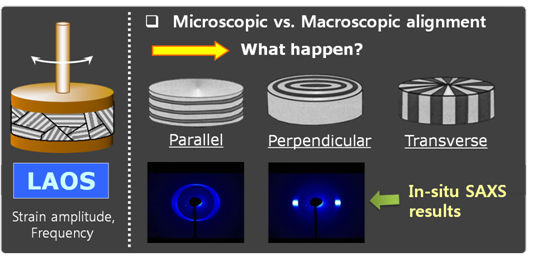

Especially, complex fluids undergo a variety of deformations (shear, and extensional flow and so on) under the processing. These deformations affect to the microstructure or nanostructure, and vice versa, these structures can also affect the mechanical property. Thus, we need to investigate an interesting coupling between internal structure and flow field. For better understanding relation between internal structure and flow field, Dr. Struth who is member of HASYLAB (DESY, Hamburg, Germany) designed new in-situ Rheo-SAXS (combination of Rheometer and X-ray) through cooperation with us. Therefore, we will investigate flow-induced alignments of complex fluid with in-situ Rheo-SAXS under applied shear. For example, the change of microstructure of blockcopolymer melts under LAOS deformations in the below figure.

Especially, complex fluids undergo a variety of deformations (shear, and extensional flow and so on) under the processing. These deformations affect to the microstructure or nanostructure, and vice versa, these structures can also affect the mechanical property. Thus, we need to investigate an interesting coupling between internal structure and flow field. For better understanding relation between internal structure and flow field, Dr. Struth who is member of HASYLAB (DESY, Hamburg, Germany) designed new in-situ Rheo-SAXS (combination of Rheometer and X-ray) through cooperation with us. Therefore, we will investigate flow-induced alignments of complex fluid with in-situ Rheo-SAXS under applied shear. For example, the change of microstructure of blockcopolymer melts under LAOS deformations in the below figure.

Chemical & Biomolecular Engineering

Chemical & Biomolecular Engineering